Industrial IoT (IIoT) bridges the difference among industrial Technology and equipment systems (normally called O-T, functions technological innovation ) and it (IT). Back in IT, usage of new systems like machine computing, computing, cell, and advantage computing have become increasingly becoming predominant. IIoT attracts servers, cloud computing systems, analytics, and also even people with each other to increase productivity, performance, and efficacy of industrial procedures allowing users to switch into IIoT software for predictive maintenance and quality and also to monitor their surgeries out of anyplace.

But knowing that the worth of IIoT is tough and generally there’s Are just 3 elements which, out of our expertise, are retaining back manufacturers

- Info is accumulated overly rarely

- Info is Hard to get

- Struggling to conquer info silos and connect info collectively

This site may research the way that industrial Businesses Can use Predictive Good quality to ascertain tasks like correcting machine configurations, with distinct origins of raw substances, or even doing other worker teaching which can enhance the essence of the outlets output signal.

By minding Reliability Edge IoT solutions, industrial Companies across various industries like mining, utilities and energy, production, precision agriculture, and petroleum and petrol may cause high quality of usable data and also enhance functionality, productivity, and efficacy.

Current Circumstance and struggles of this Business

Whether or not You’re in utilities, mining, petroleum and Gas, or every different industrial marketplace department, you’ve got heritage equipment that’s been doing work pretty well for its previous 10, 20 and maybe 30 decades ago A lot of industrial businesses have earned significant strides in usable technologies like Professional PCs (IPCs), Programmable Logic Controllers (PLCs) or huge dispersed Control Systems (DCS) with real world dispersed management networks (fieldbuses) linking themand Supervisory Control and Data Acquisition (SCADA) devices. Operational technology had been deployed and designed to survive a handful decades, therefore are profoundly entrenched, and therefore so are quite hard to displace.

In case We Would like to Gain from brand new technology such as IoT, system Finding out, and personal vision, we must accommodate present systems and equipment, that are specially constructed for IoT software.

First obstacle for Virtually Any IIoT program would be to link Legacy gear, therefore we’re ready to get info from various products (detectors, actuators( electric motors) from various manufacturing companies. In most instances we must conform to distinct marketplace protocols and on occasion maybe retro-fitting, by integrating new technologies to mature procedures therefore that they really have the ability to quantify, permit handy handheld remote controller, and also join with

The 2nd and most crucial obstacle includes collectively with The connectivity, has been still security. We’ve to continue to preserve the apparatus and its own information protected. The collapse of a gear or machine at a manufacturing environment may cause expensive downtime and impact into your own organization. We’ve to be certain industrial associated apparatus can use in the very best operation with cloud management. Datacollection procedures shouldn’t restrict the functioning of their apparatus and make sure any handy handheld remote controller or upgrade performance is achieved in a safe manner from just permitted operators.

Once We’ve Got the information procured Will Come the next obstacle, to Acquire insights. Data might be secured from several different”flooring” of this mill (diverse heights of this ISA-95 structure ). As a way to receive advice out of every one of the raw info, it’s essential to connect together the data, irrespective of in the event the info is originating from various apparatus, historians, manufacturers, fieldbuses, techniques, or even data bases.

The Way That It Works:

Reliability Edge IoT assists industrial Businesses conquer Challenges to achieve company objectives.

- To begin with, Reliability Edge IoT enables you to connect, control, and upgrade gadgets of any variety from modest microcontrollers, to powerful entry apparatus. You may incorporate your current legacy gear in the laminate flooring these as Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems by utilizing simple detectors to track procedures and monitor critical efficiency indexes without even any repainting or changing present components.

- Secondly, Reliability Edge IoT gives you builtin apparatus authentication and consent to continue to keep your IoT info and apparatus shielded. You may also always re install security guidelines related to your apparatus and track your apparatus fleet for unnatural behaviour, and also receive alarms when something does not look suitable. You may take corrective activities, like powering away apparatus or hammering a protection correct.

- 3rd, Reliability Edge IoT empowers connected apparatus to successfully manage irregular online connectivity to mitigate threats of downtime. You may conduct system learning units or applications and save information locally before Web connection can be found.

Reliability Edge IoT supplies “plug in and play” capacities That means you may scale up your IoT software into tens of thousands or thousands of apparatus. With Reliability Edge IoT, you also can arrange apparatus stock, and track your fleet of apparatus, also manage apparatus across a lot of areas such as upgrading apparatus program overtheair (OTA).

Once apparatus are firmly onboarded, Reliability Edge IoT Has an effortless solution to conduct info on IoT info. Reliability Edge IoT gathers, procedures, and assesses IoT info fast so that you may get usable insights. Reliability Edge IoT incorporates using Reliability Edge companies therefore that you may construct machine-learning units for the Industrial IoT info. All these devices learning units might run from the cloud and also will be set up everywhere in your apparatus. With Reliability Edge Condition Based Monitoring providers, you’re able to picture and research data and also share advice around groups.

From the Subsequent segment, you Will Locate a comprehensive Explanation the way many various Reliability Edge IoT providers supply significance to encourage that the many crucial industrial usage circumstances:

- Asset Situation Tracking

- Predictive Servicing

- Predictive Excellent

Leading Rated Industrial Use instances and design Walk-through

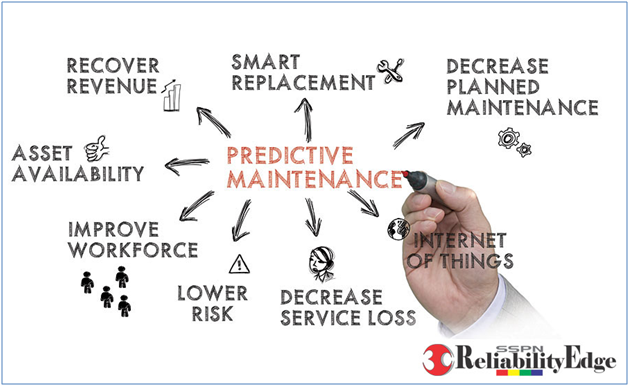

Predictive Maintenance

Predictive upkeep analytics catches the condition of Industrial gear therefore that you may identify prospective flaws until they effect generation. With Reliability Edge IoT, you may always track and finalize equipment standing, wellbeing, and operation to find dilemmas in real life. When authorities utilize predictive care analytics, devices continues more, employee security gains, and also the distribution series remains already more optimized.

In the Event You examine this particular specific design together with all the preceding person for Asset Situation Tracking you Will Find a Couple Added functionalities that Permit You to expect equipment collapse:

- Reliability Edge companies can be actually really just a fully-managed assistance which insures the whole system learning work-flow to both tag and then organize your own data, select an algorithm, then educate the version, song and enhance it to get installation, create forecasts, and also behave. Within This Particular structure,

- Reliability Edge products and services can apply existing or any custom made algorithm in addition to the blank information processed by Reliability Edge IoT Analytics. You could certainly do statistical classification by means of a procedure named logistic regression. It’s possible to even utilize Long-Short-Term memory (LSTM), and it is just really actually a potent neural network procedure for predicting the outcome state of this procedure which changes on time. The pre-built laptop templates additionally encourage the kmeans clustering algorithm to get apparatus segmentation, which clusters your apparatus in to cohorts of such as apparatus. All these templates have been usually utilized to account apparatus health insurance and apparatus condition like HVAC components at a mill or tear and wear of all blades on the wind mill.

- Reliability Edge Condition Based Monitoring providers which makes it simple to do system mastering inference anyplace on apparatus, together with models which can be generated, skilled, and optimized at the cloud system. Reliability Edge Condition Based Monitoring providers provides you the versatility to utilize machine learning units from Reliability Edge companies or to draw your very own pre-trained version saved in Reliability Edge’s Server. Inside This structure,

- The moment the predictive version is been competed in Reliability Edge Cloud, the version might be deployed in Reliability Edge Condition Based Monitoring products and services and play system mastering inference locally. In this a way you can conduct instantaneous corrective activities onto the border, locally, even in case the called version expects bad behaviour, in that case your mill is going to run on the side.

Today, let us improve the predictive upkeep reference Structure to achieve predictive caliber, that’s the objective of almost any wise manufacturing facility.

Predictive Excellence

Predictive Excellent analytics infusion actionable insights From industrial info sources like manufacturing supplies, ecological requirements, and individual observations. The aim of predictive excellent analytics would be always to find out activities like correcting system preferences or employing distinct origins of raw substances that’ll enhance the essence of the outlets output. Utilizing Reliability Edge IoT, industrial makers might assemble predictive high excellent units that aid them create far superior services and products. Top grade services and products improve client care and decrease merchandise wares.

The Advised reference structure to predictive Caliber, perhaps maybe not merely tracks their condition of the industrial gear (asset state tracking ) and forecasts failures (predictive maintenance), but in addition tracks the standard of this fabricated product through all of the ways of this manufacturing line, also with the addition of monitor and machine understanding since you are able to view at the subsequent photograph:

Within This brand fresh structure we include These components:

- Computer-vision to catch via videos or images that the product at every one of those stages. Inside This structure,

- As a result of Reliability Edge Condition Based Monitoring providers it is possible to join with some easy camera, then play the compulsory protocol translation, and also alter which camera at a wise camera by simply conducting system mastering inference in border.

- In the beginning, sufficient videos or images are uploaded into both cloud and also then stored at S-3, in order to coach an eyesight system learning version right for the merchandise. This version is going to perform exactly the discovery of products that are faulty mechanically.

- The moment the equipment learning version is trained, then we may set up this specific version from Reliability Edge Condition Based Monitoring products and services, and also conduct system mastering inference anyplace, and even in the event that you get rid of connectivity into internet, then you are going to be able to execute the inference and asses that the caliber anyplace.

Asset Integrity Management

- Asset state tracking captures the condition of One’s Machines and gear and that means that you may comprehend the method by which the strength is acting at the area or in the mill ground. On average, info like vibration, temperature, and malfunction codes suggest when devices use is best . however, it truly is tough to catch since contractors will have to inspect machinery. With Reliability Edge IoT, you’re able to catch most of of IoT info and track overall functionality. With greater visibility, then you’re able to optimize strength use and entirely harness on your financial commitment.

We propose that using the Subsequent benchmark structure to performing Asset Integrity Management (aka Condition Based Monitoring) in industrial surroundings.

Let us Evaluate the Use of every Reliability Edge IoT Products and Providers To give you a holistic Asset situation Tracking usage instance within the marketplace:

- Reliability Edge Condition Based Monitoring products and services brings nearby calculate, messaging, information caching, sync, along with m l inference capacities to border apparatus. Within This Particular usage instance, Reliability Edge Condition Based Monitoring Providers gives you

- With Reliability Edge Condition Based Monitoring products and services Connectors and long-running lambda works to incorporate with almost any present industrial protocols and apparatus. Aside from that, together with Reliability Edge Condition Based Monitoring providers you’ve accessibility into the regional means of this gate way at which it’s functioning, allowing Reliability Edge Condition Based Monitoring products and services to obtain sensor information and take care of apparatus by way of GPIO, sequential interfaces or every further interface. Reliability Edge Condition Based Monitoring products and services can join using higher-level methods such as SCADA and on occasion perhaps MES to enhance the info arriving out of your industrial apparatus also to nourish back data from your shopfloor into the MES bus. From the subsequent graphic you may find out the way Reliability Edge Condition Based Monitoring products and services can convey together with existing heritage apparatus.

- You may even operate off line. Reliability Edge Condition Based Monitoring products and services permits connected apparatus control despite having irregular connectivity into cloud. The moment the apparatus re connects, Reliability Edge Condition Based Monitoring products and services synchronizes the info on your apparatus using Reliability Edge IoT Core, supplying smooth performance no matter connectivity.

- Makes it possible to cut the price of conducting IoT software. You may acquire rich advice in a lowly price tag by scheduling your own apparatus to filter info locally (and doing machine-learning inference in the border ) and just transmit the info you require for the software towards the cloud. This lowers the the sum of uncooked data sent into the cloud, thus reducing price and raising the standard of the info you deliver into your cloud. You might also possess the ETL paradigm (Extract-Transform-Load) in the border, at which you can extract the info in your mill machines DO-ing routine conversion, so you automatically alter the information to the most suitable format then load (i.e. deliver out ) the info to Reliability Edge IoT Core.

- Reliability Edge IoT Core can be an controlled cloud computing service which enables connected apparatus readily and safely interact together with cloud computing software and also different apparatus. Reliability Edge IoT Core may encourage countless apparatus and trillions of messages, also certainly will procedure and path these messages into Reliability Edge end-points also into alternative apparatus faithfully and safely. Within This Particular usage instance,

- Reliability Edge IoT Core will filter, alter, and behave up on apparatus data around the fly, dependent on business rules that you specify. You may make utilize of the IoT regulations to have the ability to find in real time in tools and also divert the advice towards the perfect support. Inside this instance, if mistakes are found, we ship people mistakes into this Reliability Edge SNS messaging agency to ship a SMS or a email into the mill to execute action. In addition to that, each of the info has been routed into Reliability Edge IoT Analytics to get additional processing and assessing the info.

- Reliability Edge IoT Analytics can be an fully-managed assistance which produces it simple to conduct and operationalize complicated analytics about gigantic quantities of IoT info and never needing to be concerned about the price and sophistication on average expected to construct an IoT analytics system. Within This Particular usage instance,

- Reliability Edge IoT Analytics can improve the IoT info taken out of your industrial applications together using information positioned in different sourcesand may fill the openings whether info is lost, may expel fake readings and also certainly will do mathematical procedures if detectors aren’t correctly calibrated.

- Reliability Edge IoT Analytics could organize the information to be retrieved straight with Reliability Edge Condition Based Monitoring providers also to be examined together using server learning utilizing Reliability Edge products and services.

Depending on all the foundation of the design We’ve Got the Most Suitable bits To tackle the subsequent utilization instance, predictive care.

Summary

When industrial Businesses Become started constructing IoT Software, they have been frequently worried about gymnastic heritage gear. Info and apparatus stability, sudden downtime, and finding invaluable in sight out of accumulated info.

Reliability Edge IoT supplies”plug in and play” capacities To join to active gear, irrespective of what producer, extract info from apparatus and also restrain them at a safe manner and to have the required insights together with this particular specific data.

Inside This site We’ve examined that the advocated Reliability Edge IoT providers and architectures to perform Asset Situation Tracking, Predictive Care, and also Predictive Good High Top Excellent to Allow You to Readily digitize Your business.